Ever since attending last year's Welshpool Gala and spending an inordinate amount staring at it in the loop, I have been wondering how to make a model of Diema. At the time I took a good number of photographs just in case I should ever find myself in a position to model it.

In the last Llanfair Journal there was a picture of their works train headed by Diema. The train itself consists of two modified Bowaters Pulp wagons, two RNAD box vans and a Zillertal coach (to be replaced once the Mess Coach has been rebuilt). As it happens I already had my own design for the Bowaters Pulp wagons printed. There are also two RNAD vans in the stash and I have 4 Zillertal coaches so I just need the engine. This is an ideal train for my new roundy roundy (I really must decide on a name) layout.

The biggest problem is a drawing of the engine - it doesn't exist. I asked the team at Welshpool and they don't have a copy either. They did say I could go and measure it but it's a 5 hour drive each way for me. By chance, a good friend, Steve Mann, said he was going for a day trip to Welshpool and foolishly agreed to take some key measurements which would allow me to extrapolate the rest from photos. He excelled himself and now I have most of what I need.

The power unit chosen is from Narrow Japan and came within a week of ordering it. It's a very dinky unit and they do a range of wheelbases and wheel diameters so I expect I will be back for more. I calculated the wheelbase from the centres of the bearings on the photos and the wheel diameter is a best calculation based on the rail height to the centre of the bearings. After that I chose the closest match.

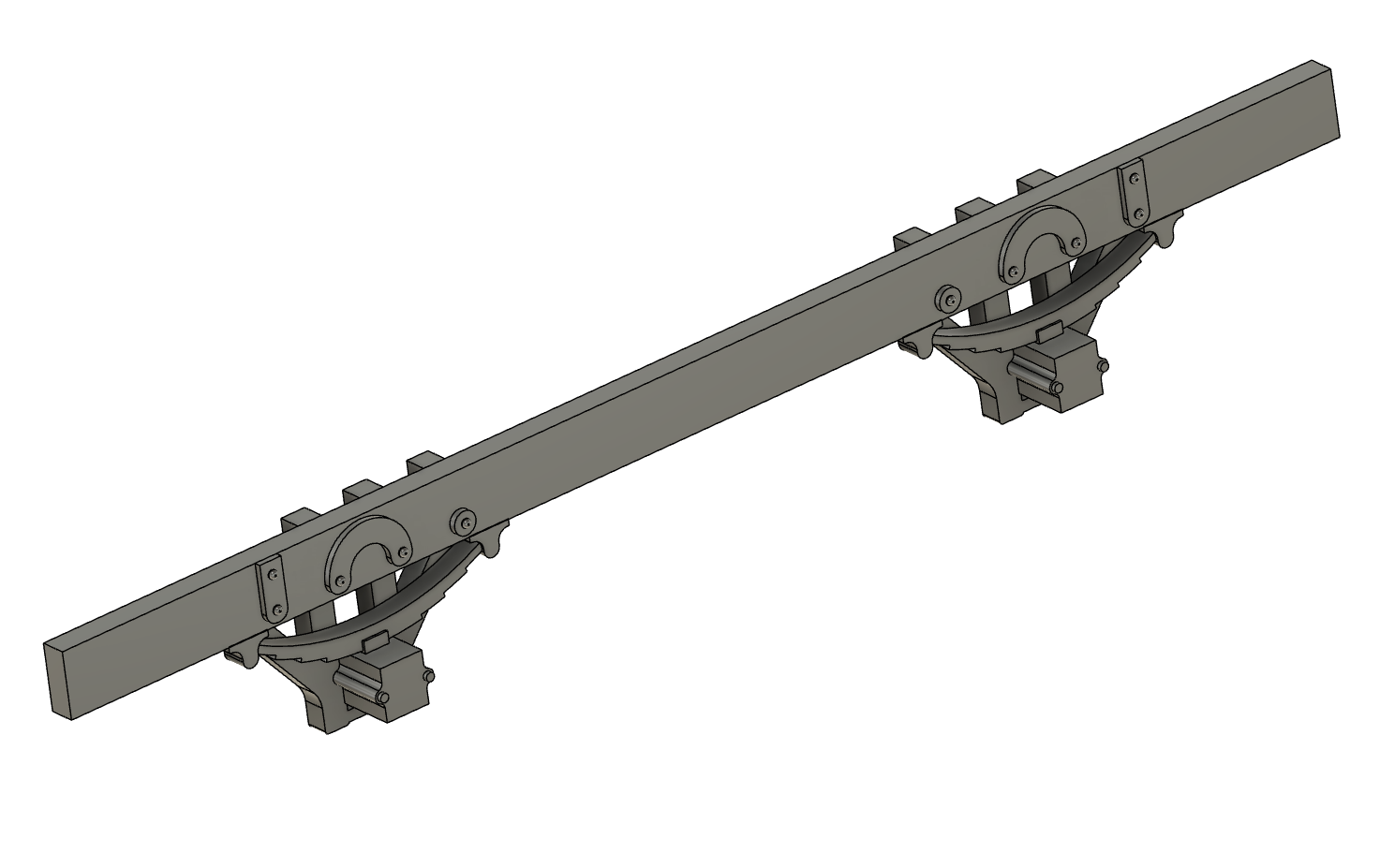

Over the past few days I have designed the body in CAD and have done some basic sizing prints just to get the fundamental dimensions right.

I find myself missing two dimensions:

- top of rail to top of footplate

- top of rail to bottom of chassis side frame

so those are guesswork for now. It was inevitable that perspective on photos is making some of the calculations harder. The body is sitting a little low but that will be fixed in the next print. For now I will work on what looks right and measure them at the Gala later this year when I am again taking Melin Dolrhyd.

Lastly, here is the basic loco posed next to The Earl to give a sense of size. It is not a tiny diesel!